Excavator Mounted Dredge Pumps

The Excavator Mounted Dredge Pumps attach to the boom arm of an excavator, allowing the operator to excavate underwater much more effectively than traditional dredges. The excavator attachment is a plug and pump system that involves quick setup time because the boom is pre-plumbed for the discharge hoses, saving on costly modifications. This dredge system gets your project started quickly and finished sooner. DAE Pumps is the leading dredge manufacturer of excavator mounted dredge pumps. We manufacture over 150 different sizes and powers to fit your exact need. Contact us today for a quote!

Excavator Mounted Dredge Pumps are a gamechanger for small to large scale dredging projects. These lake, pond, lagoon, and ocean dredging equipment allow operators to perform their dredging by mounting a 3-inch to 16-inch hydraulic excavator mounted dredge pump on the end of an excavator boom. There is no need to contract out the dredging anymore. DAE Pumps manufactures a variety of affordable heavy-duty excavator dredge pumps that move large amounts of material up to 8800 GPM with heads up to 400 feet TDH.

DAE Pumps Excavator Mounted Dredge Pump saves time and money over the traditional mechanical way of moving material. Operators would move materials from one point to another, then truck it miles away to the final location. With an excavator dredge pump attached with slurry hoses, operators can transfer rocks, gravel, slurry, sludge, and a variety of other abrasive material in just one step. Excavator pumps by DAE Pumps transport a high concentration of solids over a long distance. Their strength and durability virtually eliminate the worry of wear-and-tear and maintenance.

Growler 1000 Hydraulic Dredge Pump with 2-Side Cutters

The DAE Pumps Growler 1000 Hydraulic Dredge Pump with 2-Side Cutters is a highly durable and reliable dredge pump for transporting solids and a variety of other materials. Built with two heavy-duty excavator cutters and the industry’s top dredge pump capable of moving up to 2000 cubic meters of solids per hour, the Growler 1000 provides non-clogging suction power to excavate and pump some of the most challenging dredging situations. The suction power handles solids up to 3.9-inches.

Growler 3000 Electric Dredge Pump with 2-Side Cutters

The DAE Pumps Growler 3000 Electric Dredge Pump with 2 Side Cutters is an extremely rugged dredge pump for transporting the most abrasive solids from heavy-duty dredging situations. Two industrial-strength excavator cutters and a heavy-duty dredge pump enable the Growler 3000 to transfer up to 1200 cubic meters of material per hour through a maximum 16-inch discharge. The suction power can handle solids up to 3.9-inches and transfers up to 70% solids without clogging.

Excavator Dredge Pumps Machinery

Excavator pumps fit on a variety of equipment for operations. The Excavator Mounted Dredge Pump can be used along the shoreline and in shallow waters, but are limited to the length of the arm and access of the equipment. They perform well on the following equipment

- Excavators

- Swamp Excavators

- Swamp Buggy Excavators

- Floating Excavators

- Amphibious Excavators

- Mini Dredge Excavators

- Pontoon Excavators

- Long Reach Excavators

- Backhoes

Excavator Attachment

Excavator attachments are engineered to maximize the power and efficiency of your excavator and deliver the most productivity. The excavator attachment is designed and built for maximum performance and safety. From excavator buckets to hammers, augers, grinders, and dredge pumps, the excavator attachment makes the job easier.

The Excavator Mounted Dredge Pump outperforms both the bucket and grinder attachments combined. It can do both jobs better and more efficiently. With a dredge pump attachment, the operator can grind up rocks and boulders and move the material immediately. There is no need to switch attachments to complete the job.

The dredge pump is equipped with heavy-duty cutter heads and incredible pump suctioning power to move material immediately after breaking it up. There is no need to have the dump truck continually running back and forth with loads of material. The excavator dredge pump uses hoses to move abrasive solids and liquids to your desired location, and it can all be done quicker and cheaper.

Features of DAE Pumps Excavator Mounted Dredge Pumps

- Non-clogging

- High Viscosity

- Pumps 60% – 70% Solids

- High Specific Gravity

- High Abrasives

- No Critical Tolerances

- Low Maintenance

- Minimal Downtime

Accessories:

Along with manufacturing dredge pumps, you can also get turnkey solutions that include dredge hoses, slurry flow meters, power units, and more. Choose from multiple sizes of slurry hoses for the transferring of materials, wireless flow meters for measuring the flow rate in gallons per minute of liquid, and power units for operation. Parts are always in stock and available for immediate shipping to anywhere in the US and the world.

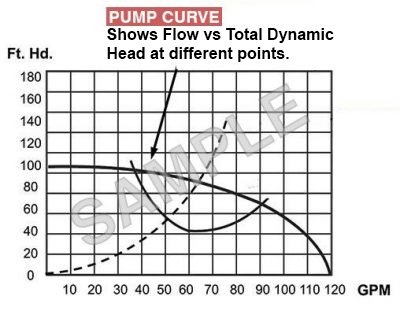

Custom Pump Curve

A pump curve is a graphical representation of a pump’s flowrate against a certain level of the head. Using a pump curve that is specific for your application will greatly help in selecting the pump best for you, ultimately saving you time and money.

Pump curves are developed from data gathered during testing of the pump’s performance at the manufacturer’s facility and provide the end-user with a graph of how the pump will operate over a set range. To build the pump curve, our engineers compile several variables, including the type of material, fluid viscosity, distance to pump, target GPM, and job-specific factors. This ensures the most efficient pump is recommended for your project.

Get in Touch

Excavator Mounted Dredge Pumps FAQs

What is an excavator dredge pump?

An excavator dredge pump is a specialized attachment designed to be mounted on hydraulic excavators for dredging and material handling tasks in waterways, rivers, lakes, and other bodies of water. These pumps harness the hydraulic power of the excavator to remove sediment, debris, and other materials from underwater environments.

How does a hydraulic dredge pump differ from traditional dredging equipment?

Hydraulic dredge pumps leverage the hydraulic power of excavators to operate, eliminating the need for dedicated power sources or pontoons associated with traditional dredging equipment. This makes them more versatile and cost-effective, allowing for precise dredging in confined spaces and remote locations.

What are the key features of hydraulic pumps for excavators?

Hydraulic pumps for excavators are designed with features to optimize performance and efficiency in dredging applications. These features may include high-capacity pumps for efficient material handling, durable construction to withstand abrasive materials and harsh environments, and adjustable flow and pressure settings to adapt to varying dredging conditions.

What types of excavators are compatible with hydraulic dredge pumps?

Hydraulic dredge pumps can be mounted on various types and sizes of hydraulic excavators, including mini excavators, compact excavators, and large crawler excavators. The compatibility of the dredge pump with the excavator depends on factors such as hydraulic flow and pressure requirements, attachment mounting options, and excavator specifications.

What are the advantages of using a dredging excavator with a hydraulic dredge pump?

Using a dredging excavator with a hydraulic dredge pump offers several advantages, including increased flexibility, mobility, and efficiency in dredging operations. These systems allow for precise control and maneuverability, enabling operators to reach confined or hard-to-reach areas with ease while minimizing environmental impact and reducing dredging costs.

How can I determine the right hydraulic dredge pump for my excavator?

Determining the right hydraulic dredge pump for your excavator involves considering factors such as the size and type of excavator, hydraulic flow and pressure capabilities, dredging depth and reach requirements, and the type of material to be dredged. Consulting with a dredging and industrial pump expert can help you select the optimal pump for your specific application and project needs.