Choosing the Right Dewatering Pump for Your Application

Dewatering Pumps for Specific Applications

Different methods of dewatering are not always interchangeable and each method has a fairly narrow range of applications. Dewatering systems in mines and on construction sites can be expensive to set up, so it is critical that the right method is selected for each specific application.

Construction Industry

Stable working conditions are essential in laying foundations for the construction of buildings, dams, and almost any other structure that involves sub-surface construction below the water table. Dewatering of an excavated area must be done to keep the bottom of the area dry and prevent leakage of groundwater, as well as rainwater and earth into the excavation.

There are four main dewatering methods used on a construction site:

Wellpoint – This method uses a series of wells, called wellpoints, that are often created in a rectangular pattern around the construction site. Dewatering riser pipes are installed into the wells and connected through a flexible swing pipe to a common header pipe. The header pipe is fitted with a vacuum pump to draw water through notches in the wellpoints and to discharge it away from the working area. This method works well up to a depth of about five or six meters. Multiple stages of wellpoints must be employed if a deeper drawdown is needed.

Eductor Wells – The eductor wells method is similar in operation to the wellpoint method. The only difference lies in the mechanism of dewatering. Instead of using a vacuum, this system operates with high-pressure water through a venturi tube in the riser units to draw off the water from the wellpoints. The main advantage of the eductor method is that the water table can be lowered by ten to forty-five meters, depending on the number of pumps used. This system is particularly economical with soils of low permeability.

Open Sump Pumping – This is the most economical method of dewatering and the most popular for that reason. Solids handling slurry pumps are used to drain the water and sludge from sumps that are created around the excavation area. Pumps used for this duty need to be robust enough to handle water with high solid content and in many cases, larger solid material. As the sumps have to be at a level below that of the excavation, fresh sumps have to be created as excavation progresses.

Deep Wellpoint – The deep wellpoint method uses wells of a larger diameter that are drilled around the excavation area. Water seeps into these wellpoints under gravity and is drawn off by submersible pumps. Wells are encased to retain their shape. Screens and filters are often used to prevent unwanted sediment from entering the well to make the work of the submersible pump easier and ensure it does not get clogged up.

Mining Industry

Throughout the mining industry, sumps are created to collect groundwater that seeps into shafts and working areas. Submersible pumps are used to pump the water to the surface. In most cases, no attempt is made to restrict the flow of this water, which requires continuous pumping to keep the working areas of the mine dry. In deep mining operations, several pump stations may have to be built to get the water up to the surface in stages.

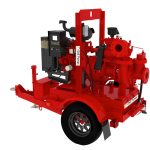

Opencast mining operations are also susceptible to groundwater seepage and the collection of rainwater. Many of these operations create sumps to induce runoff of water from working areas. This water usually contains high solids as well as solid materials, and removal requires a pump robust enough to handle this duty. Opencast mining operations generally use mobile sump pumps to dewater their working areas.

Factors Affecting the Choice of Dewatering Pump

Whatever the application, there are a number of factors that have an impact on the choice of a dewatering pump:

Solids Content – The water that collects during mine production, construction, or from flooding is not clean and contains solids. The solid content varies greatly from application to application. Generally, floodwaters have a much lower solid content than the water that collects in mining or construction operations. Solids cause abrasive wear in pumps. In the harsh conditions prevalent in the construction and mining industries, dewatering pumps need to be robust enough to withstand abrasion. Centrifugal pumps, with their low tolerances, are particularly prone to abrasive wear and will require a high level of maintenance. Ideally, pumps with better abrasive wear resistance should be chosen for these applications.

Water pH – Depending on the quality of groundwater seeping into working areas, the water that needs to be extracted may be acidic. Mine water in particular has high acidity which can cause significant pump corrosion. Dewatering pump selection must take the acidity of the water into account. High acidity may demand a pump made from a material that has high corrosion resistance, like stainless steel and other steel alloys.

Solid Material – In any flooding or water collection scenario there is always the possibility of solid material being present in the water. This makes it impossible for pumps with low tolerances to operate efficiently. Any pump selected should have sufficient tolerance to be able to handle solid material. Centrifugal pumps are generally not suitable for this purpose due to solids that could be present which could potentially clog the pump.

Need Help?

Check DAE Pumps Other Products

DAE Pumps – Going Above and Beyond!

DAE Pumps is a premium industrial slurry pumps and dredge equipment manufacturer. Offering unparalleled performance for many different industries, DAE Pumps are ideally suited for Oil & Gas, Mining, Construction, Marine, Municipal, Water & Wastewater, and many other industries. Along with the high-quality pumps DAE Pumps offers, we also provide world-class service to assist you no matter what the pumping challenge.

DAE Pumps Product Categories

All pumps by DAE Pumps are made of the highest quality materials; they are durable, long-lasting, and provide value beyond your expectations. No matter your industry, DAE Pumps has a pump specifically suited for your needs.