Centrifugal Slurry Pumps

Centrifugal slurry pumps are among the most common type of pumps found in industrial applications. A centrifugal pump contains one or more impellers that move fluid by rotation using centrifugal force. Not all centrifugal slurry pumps are the same. Many low-quality centrifugal pumps can only pump water. Their casing and impellers will only allow for this. The industrial centrifugal pump or the centrifugal slurry pumps are much more robust. They are built with heavy-duty materials that can withstand abrasive and corrosive materials. The main intent of a centrifugal slurry pump is to move solids and liquids. The durability of the centrifugal slurry pumps allows them to be used for a wide range of industries and are preferred for low viscosity liquids and high flow rates.

DAE Pumps provides a variety of centrifugal slurry pumps in multiple shapes and sizes. These industrial centrifugal pumps can process heavy abrasive solids and work through everything that would normally shut down other pumps. They are used for a variety of applications in mining, pulp & paper, agriculture, construction, oil & gas, agriculture, and many other industries. We offer dredge pumps, submersible slurry pumps, self-priming pumps, and flooded suction pumps for an extensive variety of uses.

Submersible Pumps

Self-Priming Pumps

Dredge Pumps

Flooded Suction Pumps

Features of DAE Pumps Dredge Pumps

- Capable of Pumping Wide Array of Materials

- Large Selection of Pumps and Configurations

- Pump Abrasive and Gritty Material with Ease

- High Tolerance Between Impeller and Pump Casing, Allowing Larger Solids

- Low Maintenance

Need Help Finding a Pump?

Centrifugal Slurry Pump Applications

DAE Pumps dredging equipment is ideal for a variety of applications, including dredging dams, ports, marinas, rivers, canals, lakes, ponds, and more. Ensuring water quality and capacity are essential in hydroelectric and water supply dams, making DAE Pumps dredge pumps perfect for removing excess sand and silt. Clearing sediment and contaminates from riverbeds, channels, canals, and oceans help restore safe navigation and shoreline formations, and dredging lakes and ponds clean and remove contaminants and tailing. As ocean currents move sediments, the seafloor slowly rises, lowering the depth of marinas and ports. Dredging ensures safe access for boats and other water vessels.

Centrifugal Pumps For Process Applications

- Chemical Processing

- Food Processing

- Grain Processing

- Mining

- Paper & Pulp

- Textile

- Petrochemical

- Automotive

Centrifugal Pumps For Water/Wastewater Applications

- Water Treatment

- Wastewater Systems

- Waste Collection & Disposal

- Commercial & Agricultural Irrigation

- Cooling Towers

- Marine

- Fountains

- Water Parks, Amusement Parks, & Zoos

- Commercial Swimming Pools

- HVAC Systems

- Boilers

- Dewatering

I Need Help With Selecting a Pump?

Motor & Engine Selection

Our close-coupled electric motors reduce the stress on motor bearings with a short shaft overhang and fan-cooled. Our submersible electric motors come completely enclosed with the most trusted watertight O-ring seals. Diesel engines offer self-priming features and easy to maintain capabilities. Hydraulic motors are powered by HPU or hydraulic power units and provide the utmost in capability and performance.

Centrifugal Pump Trailer Option

How Centrifugal Pumps Work

Have Questions?

What is NPSH

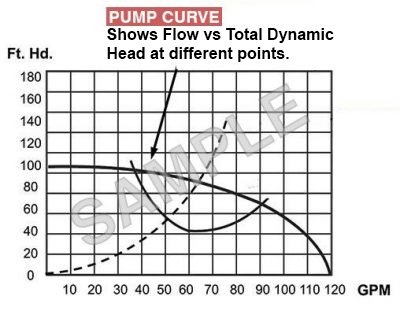

DAE Pumps provides custom pump curves per the information you provide. Including as much information about the project allow us to best match a pump with your needs, so the centrifugal pump you get is ideal for the project.

What is Cavitation in Pumps

Water can turn from a liquid state into steam or gas and boils at around 100 degrees Celsius at sea level. However, at a higher elevation, water boils at a lower temperature because of atmospheric pressure. If this pressure is less than the vapor pressure of the liquid that is pumping, then the water can reach a boiling point. When this happens, cavitation occurs.

During cavitation, air particles within the water expand, and as they reach the boiling point, they collapse in on themselves very rapidly. As they collapse, they start to damage the impeller and pump casing. This damage removes small parts of metal from the surface, and if this keeps occurring, then it will eventually destroy the pump. Therefore, you must ensure the Available pressure is higher than the Required pressure of the pump.

Pump Accessories

Custom Pump Curve

Guarantee the right pump size and power for the job with a free DAE Pumps custom pump curve for your centrifugal slurry pumps that graphically represents the pump’s flow rate of a specific head based on your exact requirements. Using a pump curve that is specific for your application will greatly help in selecting the pump best for you, ultimately saving you time and money.

Pump curves are developed from data gathered during testing of the pump’s performance at the manufacturer’s facility and provide the end-user with a graph of how the pump will operate over a set range. To build the pump curve, our engineers compile several variables, including the type of material, fluid viscosity, distance to pump, target GPM, and job-specific factors. This ensures the most efficient pump is recommended for your project. Contact a DAE Pumps representative today!

Get in Touch

Centrifugal Slurry Pumps FAQs

What is a centrifugal pump?

A centrifugal pump is a mechanical device designed to move fluids by converting rotational kinetic energy into hydrodynamic energy. These pumps are widely used in various industries for applications such as water transfer, irrigation, wastewater treatment, and chemical processing.

What distinguishes industrial centrifugal pumps from other types of pumps?

Industrial centrifugal pumps are specifically designed for heavy-duty applications in industrial settings. They are built with robust materials and construction to withstand harsh conditions and handle high flow rates and pressures efficiently. Industrial centrifugal pumps are known for their reliability, durability, and versatility in handling a wide range of fluids and operating conditions.

What are the key features of industrial centrifugal pumps?

Industrial centrifugal pumps are equipped with a range of features to ensure optimal performance and longevity. These features may include rugged casings and impellers for durability, efficient hydraulic designs for high efficiency and performance, heavy-duty bearings and shafts for reliability, and various sealing options to prevent leakage and ensure safety.

How do industrial centrifugal pumps contribute to dredging and sludge pumping operations?

Industrial centrifugal pumps play a crucial role in dredging and sludge pumping operations by efficiently transferring slurry and solids-laden fluids. Their robust construction and high flow capabilities make them ideal for handling abrasive and viscous slurries commonly encountered in dredging, mining, wastewater treatment, and industrial processes.

What industries commonly use industrial centrifugal pumps?

Industrial centrifugal pumps are used in a wide range of industries, including mining, oil and gas, wastewater treatment, chemical processing, power generation, and manufacturing. They are essential for various applications such as dewatering, slurry pumping, chemical transfer, cooling water circulation, and boiler feedwater supply.

What factors should be considered when selecting an industrial centrifugal pump?

When selecting an industrial centrifugal pump, several factors should be considered, including the type of fluid being pumped, flow rate and pressure requirements, operating conditions (such as temperature and viscosity), and system compatibility. Additionally, factors such as pump size, materials of construction, efficiency, and maintenance requirements should also be taken into account to ensure optimal performance and reliability.