Reciprocating Pumps

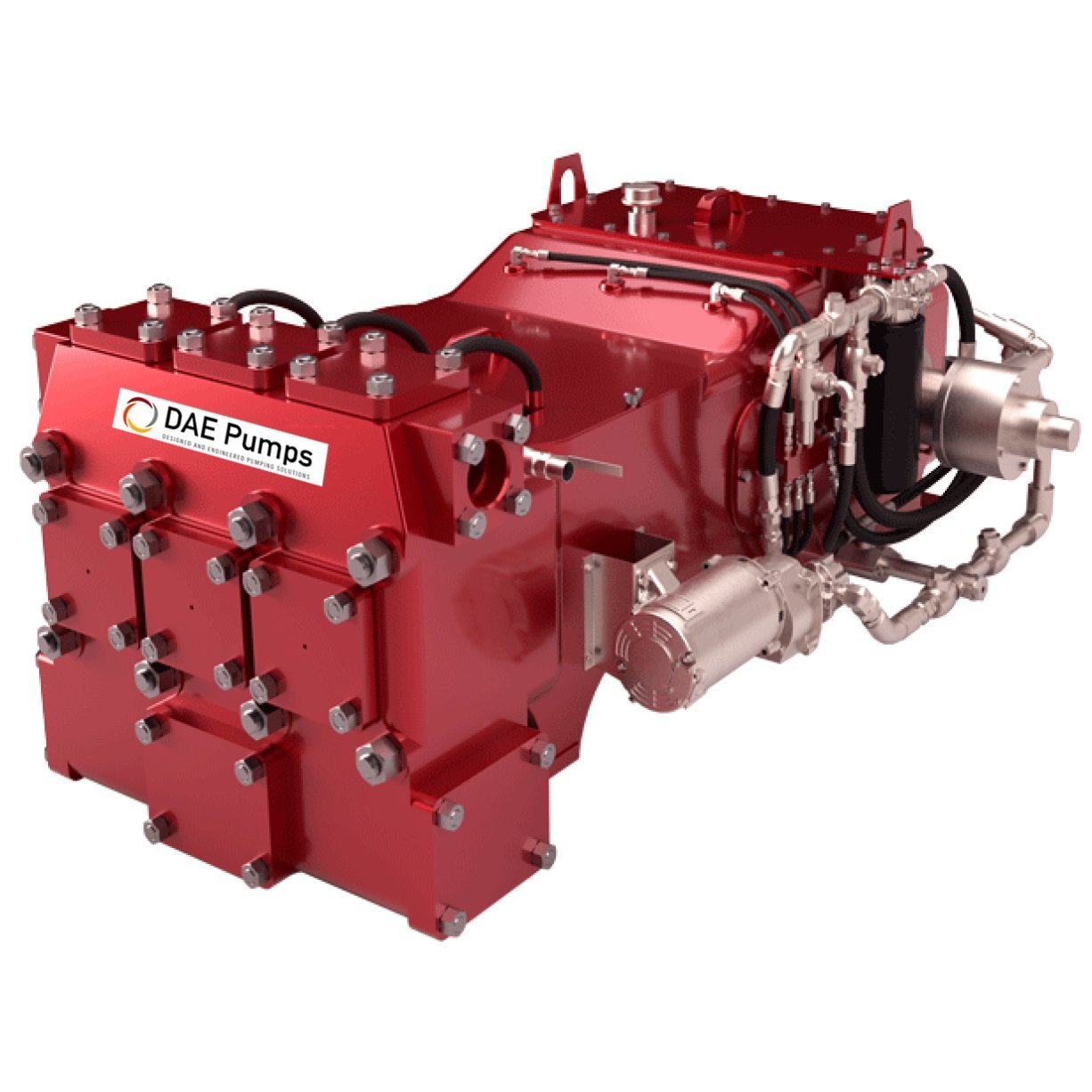

DAE Pumps’ Reciprocating power pumps are designed with exceptional versatility for more accessible product selection and faster turnaround. These units are driven via electric motors or diesel engines through a V-belt or gear. The electric motor is more popular because it is more efficient and has a lower environmental impact. The diesel engine is more powerful and is often used in industrial applications.

These units are ruggedly designed for minimum maintenance and to meet the heavy-duty requirements of continuous duty operation in the general industry. The design also includes a number of features that make it easy to use and maintain. For example, the unit is equipped with a self-lubricating bearing that requires no lubrication, and a self-cleaning filter that helps to keep the system clean and free of debris.

Get Pricing

Get Pricing on our Reciprocating Pumps

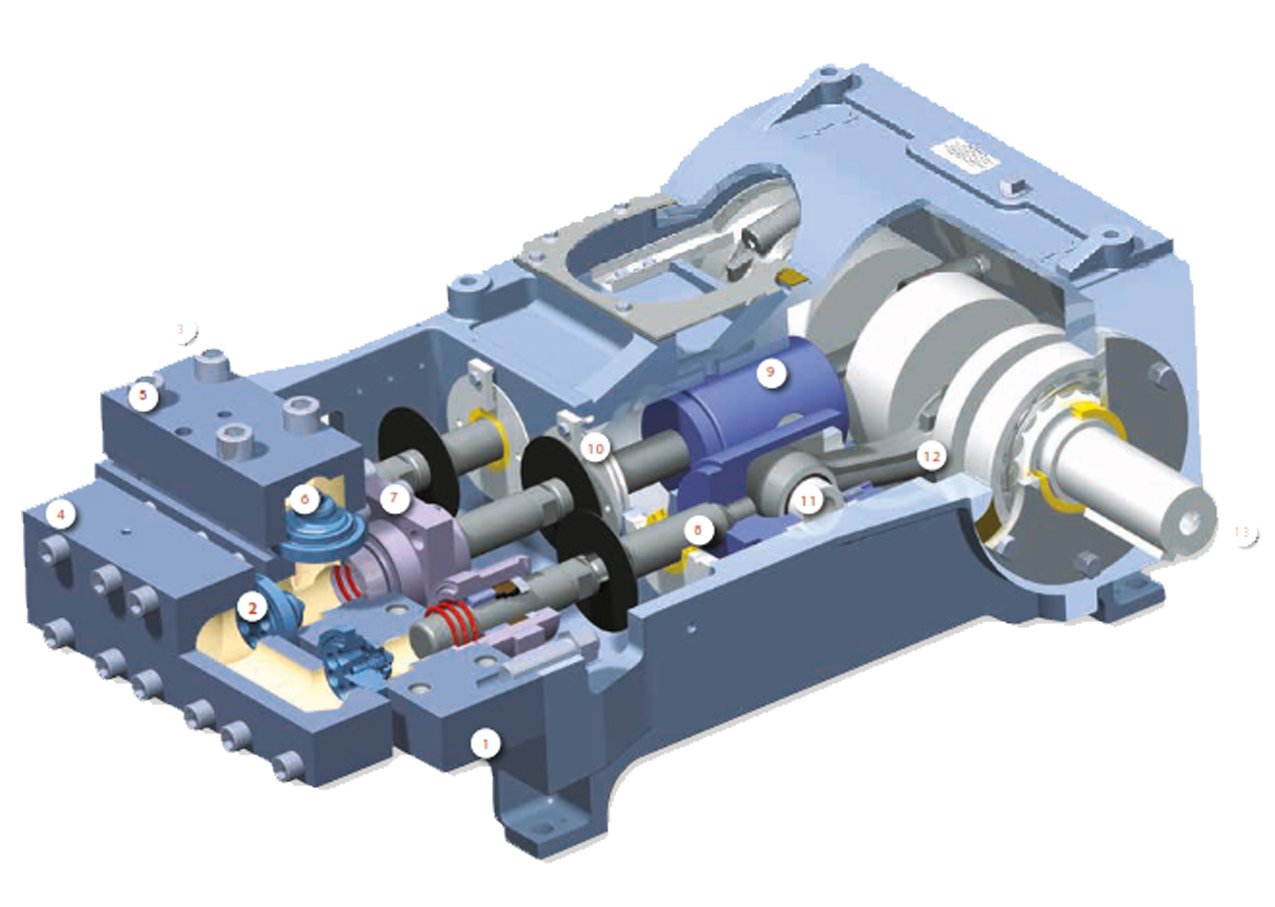

Features:

- BOLT-ON FLANGES

-

- Adapts to various system connections

- Both suction and discharge can be located on either end of the pump

-

- VALVE ASSEMBLY

-

- Vertical assemble stack designed for ease of maintenance

-

- STUFFING BOX ASSEMBLY

-

- All API 674 material options

- Standard self-adjusting spring loaded

-

- STUFFING BOX SPRING

-

- Standardized in design to improve packing life and reduce maintenance adjustments

-

- PACKING

-

- Square and V-ring design packings available

-

- PLUNGER

-

- Standard plungers are hard surfaced for long service life

-

- CROSSHEAD EXTENSION

-

- Provides accurate alignment between plunger and crosshead

-

- CROSSHEAD STUB SEAL

-

- High horsepower models use replaceable wear shoes for refurbishment

-

- CROSSHEAD

-

- Large diameter, full piston type for optimum support

-

- CONNECTING ROD & BEARING ASSEMBLY

-

- Heavy duty ductile iron or steel rods w/ separate bolted caps

-

- CRANKSHAFT

-

- One-piece SAE 4140 steel for toughness and high endurance limit

-

- CRANKSHAFT MAIN BEARINGS

-

- Two anti-friction taper roller bearings designed for 3 year L10 life

-

- POWER FRAME

-

- Full cylindrical crosshead bores that can be fitted with liners when required

-

Understanding Reciprocating Pumps: A Comprehensive Guide

Reciprocating pumps are an essential component in various industries due to their ability to handle a variety of fluids with high precision and reliability. This detailed guide provides an in-depth look at reciprocating pumps’ mechanics, types, applications, and maintenance, emphasizing their importance and functionality in very high pressure applications.

Introduction to Reciprocating Pumps (A Type of Positive Displacement Pumps)

Reciprocating pumps are a type of positive displacement pump. Unlike centrifugal pumps, which rely on rotational motion, reciprocating pumps use a back-and-forth (reciprocating) motion to move fluid. This motion allows for precise control over the volume of fluid displaced, making these positive displacement pumps ideal for applications requiring exact fluid flow rates and high pressures. This includes applications like steam pumps, power pumps, and metering pumps, where delivery pressure required must be a precise amount. With these pumps, the energy required to change the velocity of fluid in the system from at rest to a non-zero condition is called “acceleration head”.

Mechanics of a Reciprocating Pump

The reciprocating piston that moves within a cylinder is at the core of every reciprocating pump. The piston’s back and forth movement in these positive displacement pumps creates a suction and discharge process facilitated by several major components in a reciprocating pump:

-

Plunger: The moving element that displaces fluid within the cylinder.

-

Cylinder: The chamber in which the plunger moves.

-

Inlet Valve: Allows fluid to enter the cylinder.

-

Suction Pipe: Connects the fluid source to the pump.

-

Delivery Valve: Controls the fluid’s exit from the pump.

-

Suction Valve: Opens during the suction stroke to allow fluid into the cylinder.

-

Fluid Diaphragm: In specific pumps, this separates the fluid from the mechanical parts, preventing contamination and wear.

-

Piston connecting rod: In a reciprocating pump, the piston rod connects the piston to the crankshaft, transmitting linear motion to drive the pump.

Check Our Centrifugal Pumps HERE

Types of Reciprocating Pumps

Reciprocating Pumps, which are a type of positive displacement pumps, are classified into several types based on their mechanism and application:

Piston Pumps

Utilize a reciprocating piston that moves within a cylinder, creating a variable volume.

Plunger Pumps

A plunger can move fluid through a fixed packing arrangement, often used in high-pressure applications.

Diaphragm Pumps

These power pumps employ a flexible diaphragm to move fluid, ideal for handling corrosive or viscous fluids.

Metering Pumps

Designed for precise fluid delivery, they operate at a given speed and pressure to ensure exact flow rates and volume displacement.

Working Principle

The operation of a reciprocating pump involves two main strokes:

Suction Stroke: The plunger retracts, creating a vacuum that draws fluid into the cylinder through the inlet valve and suction pipe.

Discharge Stroke: The piston moves forward, pushing the fluid through the delivery valve.

The reciprocating pump displaces a fixed amount of fluid during each cycle, ensuring a consistent and precise flow rate.

Applications

Reciprocating pumps are widely used across various industries due to their ability to handle different types of fluids and their precise flow rate, unlike classic centrifugal pumps. Typical applications of a reciprocating pump include:

-

Oil and Gas Production: Injecting chemicals and transferring fluids under high pressure.

-

Chemical Processing: Employed in metering pumps for accurate dosing of chemicals.

-

Water Treatment: Utilized for precise injection of treatment chemicals.

-

Food and Beverage: Ideal for handling viscous and sensitive fluids, ensuring consistency and hygiene.

Advantages of Reciprocating Pumps

-

High-Pressure Capability: Reciprocating pumps can generate high pressures, making them suitable for demanding industrial applications.

-

Precise Flow Control: The fixed amount of liquid displaced per cycle ensures an accurate and consistent flow rate.

-

Versatility: A reciprocating pump can handle various fluids, including viscous, corrosive, and abrasive liquids and oil.

-

Durability: Designed for low maintenance costs and long service life, key to piston pumps’ overall benefits.

-

Variable speed: If it is equipped with a variable frequency drive (VFD) or another variable speed control mechanism, this allows for the adjustment of the pump’s flow rate and pressure.

Detailed Breakdown of Major Components

Plunger:

The piston or plunger is the cylinder’s moving component displacing the liquid. It is typically made from high-strength materials to withstand the stresses of continuous rate, high-pressure operation. The plunger’s durability is crucial for the longevity and reliability of the pump.

Cylinder:

The cylinder of a reciprocating pump houses the plunger, allowing fluid to move through the chamber. Cylinders are designed to handle the high pressures of the plunger’s reciprocating motion, ensuring safe and efficient operation.

Inlet Valve:

During the suction stroke, the inlet valve opens to allow liquid into the cylinder. It is designed to open under low pressure and close securely to prevent back flow during the discharge stroke.

Outlet Valve:

The fluid exits the pump cylinder through the outlet valve.

Suction Pipe:

This pipe connects the liquid source to the pump, ensuring a steady supply. The suction line must be appropriately sized and maintained to prevent air from entering the pump, which can cause cavitation and reduce efficiency.

Delivery Valve:

The delivery valve of a reciprocating pump controls liquid exit from the pump during the discharge stroke. It must open easily under high pressure and close tightly to prevent fluid from flowing back into the cylinder.

Suction Valve:

Like the inlet and outlet valves, the suction valve opens to allow liquid into the cylinder during the suction stroke. It is critical for maintaining the pump’s priming and ensuring efficient fluid handling.

Fluid Diaphragm:

Diaphragm pumps separate the liquid from the mechanical components, preventing contamination and reducing wear. This makes diaphragm pumps ideal for handling corrosive or abrasive fluids.

Maintenance of a Reciprocating Pump

Regular maintenance is essential to ensure reciprocating pumps’ optimal performance and longevity. Key maintenance practices include:

-

Regular Inspection: Inspect the plunger, connecting rod, cylinder, and valves for wear and tear. Replace any worn components to prevent leaks and maintain efficiency.

-

Lubrication: Ensure all moving parts are adequately lubricated to reduce friction and wear.

-

Cleaning: Keep the suction pipe, inlet and outlet valves, and delivery valve free from debris to prevent blockages and maintain proper flow rates.

Common Issues and Troubleshooting

Even with regular maintenance, reciprocating pumps may encounter issues. Common problems and their solutions include:

Loss of Suction: This can be caused by air leaks in the suction pipe or a blocked suction valve. Check for and seal any leaks, and clean the suction valve to restore proper operation.

Decreased Flow Rate: This may be due to wear or damage to the plunger or cylinder. Inspect and replace any worn components to restore the pump’s performance.

Excessive Noise: Noise can result from misalignment or loose components. To reduce noise and vibration, ensure that all parts are properly aligned and secured.

Advanced Applications and Innovations

Reciprocating pumps are continually evolving to meet the demands of modern industry. Innovations include:

-

Smart Pump Technology: Integration of sensors and control systems as major components to monitor and optimize pump performance in real time (key for steam pumps).

-

Material Advances: Development of new materials for plungers and the inner surface of cylinders to enhance durability and chemical resistance.

-

Energy Efficiency: Design improvements to reduce energy consumption and improve overall efficiency.

Reciprocating Pumps in Specific Industries

Oil and Gas Industry

In the oil and gas industry, reciprocating pumps often inject chemicals, transfer fluids under very high pressure, and ensure precise control over flow rates. Their ability to handle high pressure and deliver high-viscosity fluids accurately and at a continuous rate makes them indispensable in various operations, from drilling to refining to gas production.

Chemical Processing

Reciprocating pumps are crucial in chemical processing because they handle corrosive and abrasive fluids. Metering pumps, in particular, accurately diagnose chemicals, ensuring that processes remain within specified parameters. Durable materials like stainless steel for the piston or plunger and cylinder enhance the longevity of these metering pumps and resistance to harsh chemicals.

Water Treatment

In water treatment facilities, reciprocating pumps precisely inject treatment chemicals such as chlorine and fluoride, and can help with reverse osmosis. Their ability to deliver a fixed amount of liquid at a consistent rate ensures that water quality remains high and meets regulatory standards. Diaphragm pumps are especially useful in this context, as they can handle various chemicals without contamination.

Food and Beverage Industry

The food and beverage industry requires power pumps that handle sensitive and viscous fluids while maintaining hygiene standards. Reciprocating pumps meet these needs by offering precise flow control and the ability to handle a variety of fluids, from syrups to sauces. Using food-grade materials for components like the plunger and cylinder ensures that these power pumps meet strict health and safety regulations.

Advantages and Disadvantages

High-Pressure Capability: Reciprocating pumps can generate high pressures, making them suitable for demanding applications.

Precise Flow Control: The fixed amount of fluid displaced by a reciprocating pump per cycle ensures accurate and consistent flow rates.

Versatility: Capable of handling a wide range of fluids, including viscous, corrosive, and abrasive liquids.

Durability: Designed for long service life with minimal maintenance costs, especially when run by electric motors.

Applications:

DAE Pumps Reciprocating Pumps are driven via electric motors or diesel engines through V-belt or gear reduction. Stuffing boxes are designed for applications to maximize packing life and minimize maintenance. Equipment can be packaged to meet the most stringent requirements of API 674.

- Abrasive liquids & slurries

- Amonia

- Alcohol, naptha, gasoline, fueloil, lube oil

- Amine & glycol circulation

- Beverages, other viscous foods; peanut butter / corn syrup

- Blow out preventors

- Boiler feed

- Desalination high pressure feed

- Injection (chemical, saltwater, lubrication)

- Hydrostatic testing

- Hydraulic systems

- General industry services

- Product transfer

- Subsea controls

- Tars and asphalts

Accessories:

Get turnkey solutions that include dredge hoses, slurry flow meters, power units, and more. Choose from multiple sizes of slurry hoses for the transferring of materials, wireless flow meters for measuring the flow rate in gallons per minute of liquid, and power units for operation. Parts are always in stock and available for immediate shipping to anywhere in the US and the world.

Get Pricing

Get Pricing on our Reciprocating Pumps