Self-Priming Pumps

Self-priming pumps for transferring slurry, dredging, dewatering, and other harsh applications are industrial strength to provide continual suction and long-lasting use. DAE pumps make affordable heavy-duty self-priming pumps that moves debris with ease, ensuring hassle-free operation. The self-priming pumps draw liquids, solids, and other material from lakes, wetlands, sewers, construction sites, and other flooded areas to the pump where it then transfers everything to a designated area.

The DAE Pumps centrifugal self-priming pumps outperform other conventional self-priming pump in dewatering applications. A major issue with most self-priming water pumps when dewatering is the suctioning of mud and rock that destroy the pump as the water level gets too low. However, pumps by DAE Pumps are unphased as they have no issues processing the muck while constantly providing powerful suction.

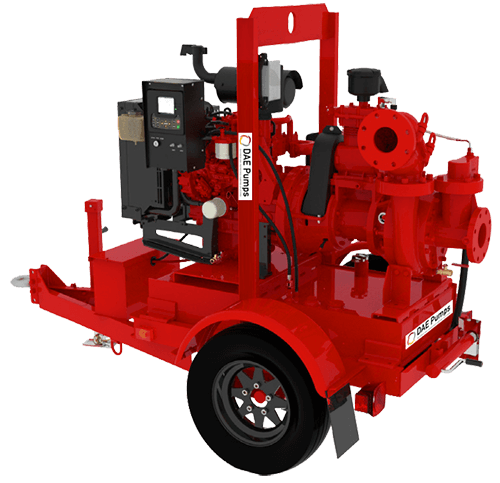

DAE Pumps offers a large selection of diesel and electric self-priming slurry pumps that mount on a trailer for easy portability or on a skid. Our self-priming pumps are excellent for diver-operated dredging. The pump and engine/motor securely located on land, and a slurry hose with a diver nozzle mounts on the head for diver-operated pumping and dredging.

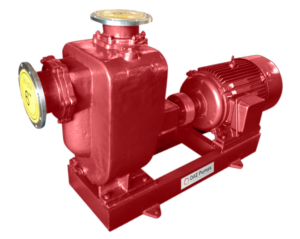

Appalachian Self-Priming Surface Pumps

The DAE Pumps Appalachian Self-Priming Surface Pumps are the industry’s most versatile dewatering surface pumps. Appalachian pumps are available in a range of sizes and power, including high head models. Pump discharges range from 3-inches to 12-inches, with maximum volume reaching 9510 GPM. Available options include towable tailor mounts or skids, and open frame or sound attenuated.

Radford Series Sewage Self-Priming Pumps

The Radford Series self-priming sewage pump of this kind has features of simple structure, good self-priming performance, high sewage capability, high efficiency and energy saving, convenient usage and maintenance, etc., compared with similar domestic products. And it belongs to the first creation in the country’s sewage pump series. Moreover, all technology and performance indexes are on top of the nation, reaching an advanced international level. So it has a broad application market and a developing future. The demand for this product is continuing to grow and expand, and there is a potential for future development.

At DAE Pumps, we pride ourselves on the quality and performance of our pumps and provide complete solutions for all your slurry pumping needs. We offer slurry hoses for transferring materials, slurry flow meters to monitor the material flow rate, hydraulic power units, and other accessories. All our parts are always in stock and available for immediate shipping to anywhere in the US and the world. Get the right pump size and power for the job with a free DAE Pumps custom pump curve that graphically represents the pump’s flow rate of a specific head based on your exact requirements.

Features of DAE Pumps Self-Priming Pumps

- Capable of Pumping Wide Array of Materials

- Large Selection of Pumps and Configurations

- Pump Abrasive and Gritty Material with Ease

- High Tolerance Between Impeller and Pump Casing, Allowing Larger Solids

- Low Maintenance

Types of Self-Priming Pumps

Self-priming pumps are used for a variety of applications and are one of the most popular types of pumps because of their robust nature. They get used in many different scenarios and for many purposes. DAE Pumps self-priming pumps are called industrial water pumps, slurry pumps, booster pumps, transfer pumps, jet pumps, dewatering pumps, surface pumps, process pumps, along with other identifiers because of the variety of applications. Sometimes these pumps are categorized for very similar purposes, but they do distinctly different functions.

Industrial Water Pumps

One of the simplest uses for the centrifugal self-priming pump is a water pump. The purpose of the self-priming water pump is just that, to pump water. Standard water pumps only move water, but when particles, rocks, mud, or other element get mixed in, they clog and wear down very fast. You can find water pumps in vehicles, residential pools, and other light-duty applications but the DAE Pumps industrial self-priming water pumps are capable of pumping water with abrasive solids mixtures of rocks, sand, twine, and other slurries. These reliable industrial water pumps are fire pumps, dewatering pumps at construction sites, irrigation pumps on farms, and for wastewater applications to clean tanks and containers.

Slurry Pumps

A robust self-priming pump that pumps more than just water is called a slurry pump. Slurry pumps move materials with viscosities up to 70% with the primary intent of moving solids over fluids. Slurry can consist of a variety of materials like mud, rocks, sand, food, vegetation, ropes, waste, tires, and anything else that can dirty up water.

DAE Pumps makes a variety of heavy-duty slurry pumps that are self-priming and can transfer large amounts of debris. Our size selection of self-priming slurry pumps meets the highest industry standards in durable metal hardness and volume pumping capabilities. DAE Pumps slurry pumps are used at mining and construction sites, on farms, at wastewater treatment plants, by a variety of city municipalities, in food processing, and a slue of other industries for several applications.

Booster Pumps

Booster pumps are additional self-priming pumps used to extend the length of pumping capabilities. Pumps can move fluids at a certain distance and height, called the head. The amount of material it can move at the max head is called the max capacity. Once reaching the max head, the flow capacity drops off, so a second, third, fourth, or infinite number of additional pumps may be needed to get to the final destination. These extra pumps are booster pumps. Requiring multiple booster pumps is common in pumping when needing to reach extended lengths and heights. DAE Pumps can help you set-up complete pump systems with any amount of booster pumps you need.

Need Help Selecting a Pump?

For help selecting the most efficient pump for your project, call us at (760) 821-8112 or submit a request.

Transfer Pumps

The transfer pump is a pump that transfers materials, such as water or solids, from one location to another. Transfer pumps move fluids from tailing ponds at mining operations, product in food processing plants, pulp mixtures and chemicals in making paper, oil & gas, fluids in drinks, and thousands of other applications. These self-priming pumps transfer material from tanks, containers, ponds, lakes, bins, and transport vehicles to the next destination. Self-priming pumps are ideal transfer pumps for their ease of use and reliability.

Jet Pumps

The jet pump is another application name of a centrifugal self-priming pump. They are ideal in supplying freshwater to farms, homes, and cabins where the suction lift is less than 90-feet. The jet pump can access the water supply in shallow wells to simplify the process of acquiring drinking water.

Dewatering Pumps

DAE Pumps self-priming pumps make an excellent dewatering pump used for removing water from the soil. Dewatering pumps get used at wellpoints and deep wells for suctioning underground water at the water table, removing floodwater caused by heavy rain, as bypasses for pipe breaks, and other applications. Dewatering of an excavated area is necessary for keeping the bottom dry and prevent leakage of groundwater, as well as rainwater and earth into the excavation. Self-priming pumps are ideal for their portability when mounted to a trailer. These types of dewatering pumps are moved from location to locations as multi-application tools, in emergencies, and for quick access.

Surface Pumps

The surface pump is pumping water off the surface of the ground. Often, when heavy rains occur, low lying areas flood. Water collects in construction sites, excavated mines, and buildings, creating a sump, and the surface pump removes the collected water and debris. Surface pumps remove or divert water from lakes, ponds, streams, rivers, and other bodies of water. DAE Pumps self-priming centrifugal pumps provide the power and capabilities to move large quantities of water through their high volume and pressure.

Process Pumps

Process pumps continually perform the same process of pumping the same material day in and day out. The DAE Pumps centrifugal self-priming pumps make an excellent process pump. They are capable of performing the same act again and again with minimal maintenance and worry-free operation. Process pumps are in many applications from industrial to oil & gas and a vast array of production settings. The DAE Pumps process pumps are low priced, and their reliability makes them in high demand.

Need Help Selecting a Pump?

For help selecting the most efficient pump for your project, call us at (760) 821-8112 or submit a request.

Accessories:

Get turnkey solutions that include dredge hoses, slurry flow meters, power units, and more. Choose from multiple sizes of slurry hoses for the transferring of materials, wireless flow meters for measuring the flow rate in gallons per minute of liquid, and power units for operation. Parts are always in stock and available for immediate shipping to anywhere in the US and the world.

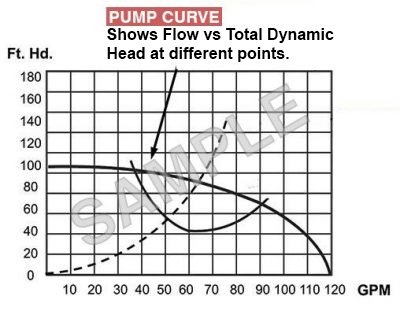

Custom Pump Curve

A pump curve is a graphical representation of a pump’s flowrate against a certain level of the head. Using a pump curve that is specific for your application will greatly help in selecting the pump best for you, ultimately saving you time and money.

Pump curves are developed from data gathered during testing of the pump’s performance at the manufacturer’s facility and provide the end-user with a graph of how the pump will operate over a set range. To build the pump curve, our engineers compile several variables, including the type of material, fluid viscosity, distance to pump, target GPM, and job-specific factors. This ensures the most efficient pump is recommended for your project.