Flooded Suction Pumps

Flooded suction pumps, both vertical and horizontal, move slurry and liquid from tanks, hoppers, and other storage systems to another system. A flooded suction pump is installed on the outside and towards the bottom or below the liquid. The liquid uses gravity to feed the flooded suction pump, always keep it primed. Priming a pump is crucial in its operation. Because the chamber and piping inside the pump are always filled with water, starting and stopping flooded suction pumps are quick and easy. The horizontal pump style is more common than the vertical pump style. Horizontal flooded suction pumps offer easy maintenance. The vertical design is offered when working with limited installation space.

DAE Pumps designs and engineers top-of-the-line heavy-duty vertical and horizontal flooded suction pumps with non-clog impellers and reliability you can trust. We build quality pumps to the industry’s top requirements at affordable prices. Contact us today for help selecting a pump!

H-Series Horizontal Flooded Suction Pumps

Horizontal flooded suction pumps use gravity to feed slurry or liquid that is above the pump. The heavy-duty flooded suction horizontal pumps by DAE Pumps see use in all kinds of applications. These affordable to operate pumps minimize downtime and improve productivity by pumping solids with ease using non-clog impellers.

V-Series Vertical Flooded Suction Pumps

The heavy-duty vertical flooded suction pumps by DAE Pumps are ideal when there is limited space for install and see use in all types of applications. Flooded suction vertical pumps use gravity to feed slurry or liquid that is above the pump. These affordable to operate pumps minimize downtime and improve productivity by pumping solids with ease using non-clog impellers.

SPW-Series Flooded Suction Pumps

DAE Pumps SPW-Series Flooded Suction Pumps are centrifugal pumps that use gravity to feed slurry and liquid from tanks and hoppers to the pump with flow rates up to 16,000 GPM. The SPW-Series carries a variety of pump sizes with intakes ranging from 1.5- to 14-inches and discharges between 1- and 12-inch. non-clog impellers.

About Flooded Suction Pumps

Flooded suction pumps can be used for a variety of applications. They can be used for agriculture, oil and gas, sand and gravel pumping, mining, and many other pumping applications. Flooded suction pumps are similar to submersible pumps, other than that they are not in the liquid. These gravity-fed pumps do not require a vacuum pump for priming. Flooded suction systems consist of a pump and motor. The motor is typically an electrically driven pump with a variable frequency drive (VFD). The VFD monitors the start-up and speed of the pump. It monitors how much RPM the pump is running to control the flow and pressure. Another type of motor used for these pumps, but less common, are diesel driven.

Liquid must be consistently feeding the flooded suction equipment to prevent damage. If the material is too thick, air can build up, and a vacuum pump or self-priming pump may be necessary to help pull the liquid to the pump. DAE Pumps also carries a variety of self-priming pumps if this may occur.

Features of DAE Pumps Flooded Suction Pumps

- Capable of Pumping Wide Array of Materials

- Large Selection of Pumps and Configurations

- Pump Abrasive and Gritty Material with Ease

- High Tolerance Between Impeller and Pump Casing, Allowing Larger Solids

- Low Maintenance

Advantages of Flooded Suction Pump

- Always primed because the liquid is gravity fed directly into the pump

- Easier and quicker to turn on and off

- Highly efficient because they do not need to use too much energy suctioning liquid to the pump

- Easy to access and maintain since they are mounted outside of the tank or hopper

Disadvantages of Flooded Suction Pump

-

No way to completely block off the suction within the pumping chamber unless there is a separate suction valve when doing repairs

-

Too thick of mixture can cause air pockets and cause the pump to lose prime

-

The consistent liquid in the pumps and pipes cause corrosion

Pump Accessories

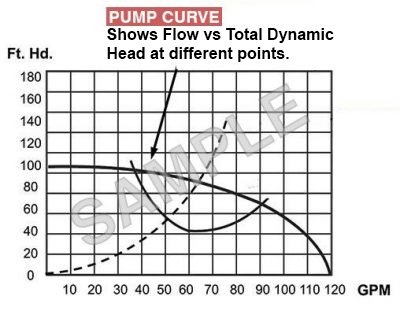

Custom Pump Curve

A pump curve is a graphical representation of a pump’s flowrate against a certain level of the head. Using a pump curve that is accurate for your application will greatly help in selecting the correct pump, ultimately saving you time and money.

Pump curves are developed from data gathered during testing of the pump’s performance at the manufacturer’s facility and provide the end-user with a graph of how the pump will operate over a set range. To build the pump curve, our engineers compile several variables, including the type of material, fluid viscosity, distance to pump, target GPM, and job-specific factors. This ensures the most efficient pump is recommended for your project.

Get in Touch

Flooded Suction Pumps FAQs

What are flooded suction pumps?

Flooded suction pumps, also known as sucker pumps, are specialized pumps designed to handle large volumes of water quickly and efficiently during flood events or water management operations. These pumps are essential for removing excess water from flooded areas to prevent property damage and ensure safety.

How do flood pumps differ from other types of pumps?

Flood pumps are specifically designed to handle high volumes of water and debris commonly encountered during flood events or emergency water management situations. Unlike standard pumps, flooded suction pumps feature a suction inlet located below the water level, allowing them to self-prime and efficiently evacuate water from flooded areas.

What are the key features of flood pumps?

Flood pumps are equipped with features to optimize performance and reliability in flood control and water management applications. These features may include high-capacity pumps for rapid water removal, rugged construction for durability in harsh environments, and self-priming capabilities to quickly establish suction and begin pumping.

How do flood pumps contribute to flood mitigation efforts?

Flood pumps play a critical role in flood mitigation efforts by quickly removing excess water from flooded areas, thereby reducing the risk of property damage, infrastructure failure, and personal injury. These pumps are essential for controlling water levels in rivers, lakes, and other bodies of water during flood events and facilitating rapid recovery and cleanup efforts.

What types of applications are suitable for flood pumps?

Flood pumps are suitable for a wide range of applications, including flood control, emergency water management, stormwater drainage, agricultural irrigation, and construction dewatering. These pumps are commonly used in urban and rural areas, industrial facilities, construction sites, and agricultural fields to manage water levels and prevent flooding.

How can I select the right pump for flood control and water management?

Selecting the right pump for flood control and water management depends on factors such as the size and severity of the flood, the volume of water to be pumped, the type of debris or solids present in the water, and the availability of power sources. Consulting with a dredging and industrial pump expert can help you choose the appropriate pump for your specific flood control needs and ensure effective water management during emergencies.