Screw Pumps – Marine

Screw Pumps – Marine

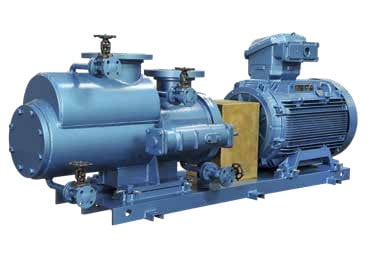

DAE Pumps Screw Pump – Marine is of the positive displacement axial flow screw type with only three moving parts – a power rotor and two idler rotors. These three rotors have accurately machined precisely intermeshing threads which enfold the liquid being pumped and act as seals about each other and to the pump body or sleeve in which they rotate. The pump body is usually made of metal, and the seals are rubber. The seals work by keeping the fluid inside the pump from leaking out. The pump body usually has a handle to rotate the pump.

Designed for pumping oils, the Screw Pump -Marine has an axial pulse-free flow and silent operation for sensitive forced lubrication, seal oil circulation, and oil firing systems. Pumps are available in 17 frame sizes with various pitch angles and lengths, offering a vast flow and pressure range. The different frame sizes allow for a variety of different applications, and the pitch angles and lengths can be customized to fit the needs of each individual project. This makes the pumps ideal for a wide range of industries, from agriculture to manufacturing.

Get Pricing

Screw Pumps – Marine

Features:

- Silent running

- Environmentally acceptable for site operators

- Pulse free flow

- Ensures no emulsification of liquid, ideal for shear-sensitive liquids

- Vibration free

- No costly foundations are required nor transmitted vibration through the system to downstream equipment

- Compact design

- Lower capital cost and space-saving installation

- High operational speed

- No intermediate speed reducers required; can run directly from high-speed power take-off, e.g., gearboxes

- High volumetric efficiency

- Low running costs

Screw Pump – Marine Usage

DAE Pumps Screw Pump – Marine can be used on any clean lubricating liquid chemically compatible with construction materials.

-

- Lubricating Oil

- Hydraulic Oil

- Orimulsion

- Distillate Fuel Oil

- Residual Fuel Oil

- Crude Oil

- Grease

- Bitumen / Asphalt

- Viscose

- Fats

- Plasticizers

- Printing Inks

The lower viscosity limit is two cSt (gas oil at ambient temperature). This limit ensures that there is sufficient film strength for hydrodynamic support. The upper viscosity limit of 1750 cSt is determined by the standard mechanical seals’ operating limit. At reduced speed and an alternative mechanical seal, viscosities up to 5000 cSt can be accommodated.

Applications:

The Screw Machine range is designed for medium pressure high flow applications on clean liquids.

-

- Lube Oil Transfer

- Fuel Oil Transfer

- Orimulsion Transfer and Firing

- Scavenging

- Fuel Oil Pumping and Heating Sets

- Duplex Pump and Filter Sets

- Rail/Road Car Loading and Unloading

- Hydraulic Power Packs

- Watertight Door Operation

- Elevator / Lift Pumps

- Variable Pitch Propeller Control

- Bitumen Production and Loading

- Fats Transfer

- iscose Production

Accessories:

Get turnkey solutions that include dredge hoses, slurry flow meters, power units, and more. Choose from multiple sizes of slurry hoses for the transferring of materials, wireless flow meters for measuring the flow rate in gallons per minute of liquid, and power units for operation. Parts are always in stock and available for immediate shipping to anywhere in the US and the world.