Application of Slurry Recirculation Pumps

September 15, 2022

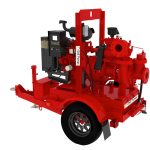

Although all industrial pumps must withstand extreme conditions, few machinery items are subject to as much vibration and abrasion as the Slurry Pump. The slurry pump is designed to handle thick material mixtures and move large amounts of debris with minimal wear. In addition, the DAE Pumps can be used for recirculation pumps. Whatever the purpose of slurry recycling, there is likely a way that slurry pumps can be used to accomplish it. These are the seven most popular slurries or sludge applications used in slurry recirculation across various industrial, manufacturing, and processing sectors.

The DAE Pump has an open rotor design that allows anything to pass through the discharge. As a result, the pump can pass more significant solids without requiring more wear to critical parts. This results in less maintenance and less downtime. Additionally, this means that the machine can be used for longer periods without issue and that it will be able to handle more strenuous tasks without breaking down. This is a major advantage for any business that relies on heavy machinery to get the job done. With a reliable and sturdy machine, businesses can avoid costly repairs and downtime and focus on getting the job done quickly and efficiently.

This Article Includes

-

Sludge Storage Mixing and Recirculation: Problems

-

Trouble, Keep Your Grit in Suspension

-

Problems with Sump, Railcar, and Slurry Tank Mixing

-

Backflow prevention problems

-

Mining Froth Flotation Efficiency

Need Help?

Our team of engineers is standing by to help you with your next project. Call us at (760) 821-8112 or submit a request.

Sludge Storage Mixing and Recirculation: Problems

You can either make sludge as a side effect or as part of a process step for hundreds of applications. These include making animal feed and dewatering construction sites. Sludge is a mix of water and suspended particulates. These holding tanks will eventually need to be empty of the particulate. For wastewater treatment and intermediate production of feeds, sludge mixing is essential. Because of their open design, slurry pumps make a great choice for recirculating sludge. This prevents internal wear and clogging.

Many times, sludge stored in large settling tanks or digester tanks must be kept suspended. A submersible DAE Pump can keep the slurry in the tank circulating, ensuring that the sediment is well-mixed. You can also install valves in the DAE pump recirculation system, which allows the slurry to be released through a separate discharge hose after reaching a certain material threshold. The entire process will run smoothly and conform to industry regulations.

Trouble, Keep Your Grit in Suspension

The only way filters and traps can catch grit is if they are suspended in steady water flows. A recirculating pump with slurry pumps can be a good way to get people’s attention where it settles. DAE pumps can withstand high levels of grit collection and pump with minimal wear due to their ultra-recessed rotors and the strength of the vortex current.

It is essential that grit be kept in suspension when using various wastewater systems. This will allow the wastewater to flow further downstream without it settling on the bottom of the tank. This is done by thoroughly mixing the solution. It prevents it from setting at the bottom of any tank. It is an important step because if the solution were to be set at the bottom of the tank, it would not be as effective.

Check DAE Pumps Other Products

Problems with Sump, Railcar, and Slurry Tank Mixing

Refrigerated and liquid storage cars, as well as refrigerated vehicles, allow affordable transportation of bulk material for the production of food and medicine. All of these mixtures can separate or thicken over time, which makes it almost impossible to return the materials to the tank. Recirculating pumps are a great way to mix materials quickly to their original suspension and viscosity. Slurry pumps are ideal for delicate fabrics, which can not be heated or exposed to excessive air. They offer an enclosed system that allows you to mix directly in a train car or settling tank.

Railcar slurries need to be stirred constantly depending on what type they are. There are many ways to accomplish this. DAE pumps are a better option for certain applications. They circulate the slurry and help keep solids suspended, preventing them from settling at the bottom. It is faster and easier to transport the material to another destination if the material has been sufficiently stirred. This is because the material will be more evenly mixed and will thus be less likely to settle into clumps. Also, starting the material will help prevent it from sticking to the sides of the container, making it easier to pour.

Backflow prevention problems

Backflow is the unintentional reversal in the flow of liquids, gases, or suspended solids slurry, into an area that does not belong. A slurry pump designed for this purpose can prevent backflow from occurring. Cross connections are points where a suspended solids or slurry system is connected with another plan. These connections are standard in household appliances like clothes washers or dishwashers. However, they should be designed carefully and installed to avoid backflow. A common place for a backflow prevention device is to connect a fire sprinkler to the water central. This prevents pressurized water from the fire suppression system to the public water supply. By having a dedicated water line for the fire suppression system, we can be sure that the water pressure will be high enough to extinguish a fire. Plus, this will keep the water from the fire suppression system from contaminating the public water supply.

Mining Froth Flotation Efficiency

The most efficient way to refine copper or other low-grade ores is using flotation in mining. It is used extensively in refining and mining, as well as in paper pulp production and wastewater treatment fluctuation. The Froth method relies on a mixture of oil and acids that cause particles to stick together and thorough stirring to create turbulence. Recirculating positions can provide the essential characteristics of slurry pumps. As a result, they are not susceptible to rusting from exposure to frothing agents.

To maximize bitumen production, Froth flotation pumping can also be used. Many centrifugal pumps are being replaced to increase bitumen production and reduce inefficiencies. Pumping can be done by degassing foam and pumping it with secondary impellers. Inducers that extract bitumen and heavier water from the air may also work. You can also collapse the air pockets by recirculating some slurry back to the eye or injecting hot water into the suction. This process helps break up the solidified slurry and makes removing it more accessible.

DAE Pumps – Going Above and Beyond!

DAE Pumps is a premium industrial slurry pumps and dredge equipment manufacturer. Offering unparalleled performance for many different industries, DAE Pumps are ideally suited for Oil & Gas, Mining, Construction, Marine, Municipal, Water & Wastewater, and many other industries. Along with the high-quality pumps DAE Pumps offers, we also provide world-class service to assist you no matter what the pumping challenge.

DAE Pumps Product Categories

All pumps by DAE Pumps are made of the highest quality materials; they are durable, long-lasting, and provide value beyond your expectations. No matter your industry, DAE Pumps has a pump specifically suited for your needs.

Need Help?

Our team of engineers is standing by to help you with your next project. Call us at (760) 821-8112 or submit a request.