The Facts You Should Know about Flooded Suction Pumps

September 08, 2022

Please find out about a flooded suction pump’s benefits and deployment options and how they differ from submersible pumps.

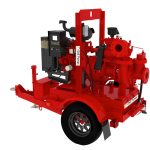

DAE Pumps’ flooded suction pumps are a type of centrifugal pump designed to operate with the pump’s inlet submerged in the fluid being pumped. The pump draws fluid into the channel and then uses centrifugal force to fling the fluid outwards towards the outlet. This process repeats continuously, with the pump pulling in more fluid and projecting it outwards in a never-ending cycle.

This Article Includes

- An Overview of Common Flooded Suction Types

- What is a Flooded Suction Pump?

- What are the advantages and disadvantages associated with Flooded Pumps?

Need Help?

Our team of engineers is standing by to help you with your next project. Call us at (760) 821-8112 or submit a request.

An Overview of Common Flooded Suction Types

Like any pump, a flood suction pump can be used to move liquids. Submersible pumps and flooded pumps have the same purpose, but the flooded suction is gravity fed. The pump is placed outside of the tank or the hopper that contains the liquid. The flooded pump is usually placed underneath or at the bottom of the tank or hopper. This allows gravity to supply the fluid during pump operation continuously. The pump can always be primed so it doesn’t lose its priming or take in too much air.

There are many applications for flood suction pumps. These pumps have both advantages and disadvantages that must be considered when choosing the right type of slurry pump to suit your needs. Other aspects that should be considered by the customer when selecting a slurry pump include the type of slurry being pumped, the distance the slurry must be transported, and the amount of time the pump will be in operation.

Flooded suction pumps can maintain their prime. Fluid exits the pump immediately after the operating mode switch from off to ON is made. Pumps in an unflooded suction environment require fluid to be pre-filled and discharged. Flooded suction pumps need a valve to connect with the inlet. This allows the fluid to drain from the pump and can then be shut off when not being used.

What is a Flooded Suction Pump?

A flooded suction pump uses gravity to feed the liquid to be pumped. This pump does not need to be primed. There are many kinds of a flooded suction pumps. The flood suction pump application differs from a submersible application. A flooded suction pump is a pump that’s located out of the fluid being pumped. The pump and motor in a submersible pump application are found inside the fluid being pumped. For flooded suction pump applications, it is common to use soft-start or variable-frequency motors.

VFDs monitor pump startup and allow for control of flow and pressure. The direct-drive diesel-powered pump is an alternative power source to a flooded sucking pump. It is used for external hopper pumps, such as those that are used to pump sand, gravel, or drilling mud. The pump is usually made of cast iron, which makes it durable and long-lasting. The pump is also designed to be able to handle high pressures, making it ideal for use in construction or mining applications.

It would help if you didn’t make the material too dense or viscous. Otherwise, the pump may not be able to feed it properly, leading to air pockets. Pumps and other equipment can be damaged by fluid that is not constantly fed. A vacuum pump, self-priming pump, or slurry pump might be required to pump the thick material. This will prevent any air buildup.

Check Out DAE Pumps Other Products

What are the advantages and disadvantages associated with Flooded Pumps?

There are many advantages to the flooded suction pump over other pumps.

Priming: Because the fluid they’ll be pumping is gravity-fed directly into the pump and always keeps it primed, the pumps are pre-primed automatically.

Pump efficiency: A submerged pump has positive fluid pressure at its inlet. This can improve efficiency because it requires less energy to pump fluid. The pump can also be designed to work in reverse, using the fluid pressure to generate electricity.

Accessibility and Maintenance: The pump should be accessible from outside the fluid used. The pump should have a shut-off valve located at the outlet. This will enable the fluid flow to the pump to be turned off, and the pump can then be removed.

However, there are some drawbacks.

Potentiality to Lose Prime: To prevent this, the mixture must maintain sufficient fluidity to feed the pump continuously.

Corrosion: Is caused by prolonged exposure to any liquid. For other corrosive or abrasive liquids, submersible pumps can be used. However, the motor can be damaged or leak from seals prone to corrosion. These pumps must be constructed from corrosion-resistant materials to counteract the effects of corrosion. They can also cost more than similar pumps.

Flooded suction pumps need to be checked as frequently as possible. This will allow you to make necessary repairs and prolong the pump’s life.

DAE Pumps – Going Above and Beyond!

DAE Pumps is a premium industrial slurry pumps and dredge equipment manufacturer. Offering unparalleled performance for many different industries, DAE Pumps are ideally suited for Oil & Gas, Mining, Construction, Marine, Municipal, Water & Wastewater, and many other industries. Along with the high-quality pumps DAE Pumps offers, we also provide world-class service to assist you no matter what the pumping challenge.

DAE Pumps Product Categories

All pumps by DAE Pumps are made of the highest quality materials; they are durable, long-lasting, and provide value beyond your expectations. No matter your industry, DAE Pumps has a pump specifically suited for your needs.

Need Help?

Our team of engineers is standing by to help you with your next project. Call us at (760) 821-8112 or submit a request.