DAE Pumps Products Specifications

Dredge Pumps

Cable Deployed Pumps Specifications

Growler 1000 Hydraulic Dredge Pump with 2 Side Cutters

| Model | |

|---|---|

| 3-inch Growler 1000 | ENG |

| 4-inch Growler 1000 | ENG |

| 6-inch Growler 1000 | ENG |

| 8-inch Growler 1000 | ENG |

| 10-inch Growler 1000 | ENG |

Growler 3000 Hydraulic Dredge Pump with 2 Side Cutters

Excavator Attachments

Growler 1000 Hydraulic Dredge Pump with 2 Side Cutters

| Model | |

|---|---|

| 3-inch Growler 1000 | ENG |

| 4-inch Growler 1000 | ENG |

| 6-inch Growler 1000 | ENG |

| 8-inch Growler 1000 | ENG |

| 10-inch Growler 1000 | ENG |

Growler 3000 Hydraulic Dredge Pump with 2 Side Cutters

Pontoon Dredge Pumps

A-Frame Mini Dredge

Silt-Bot Mini Dredge

| Model | |

|---|---|

| Silt-Bot 4-Inch Electric Mini Dredge | ENG |

| Silt-Bot 4-Inch Electric Mini Dredge | ENG |

| Silt-Bot 6-Inch Electric Mini Dredge | ENG |

Sediment Slayer Pond Dredge

| Model | |

|---|---|

| Sediment Slayer Pond Dredge | ENG |

Slurry Pumps

Centrifugal Pumps

Submersible Pumps

Electric

Sludge Electric Submersible Pumps Specifications

Sonora Submersible Sludge Pumps

| Model | Power | Volume | Head | Discharge | |

|---|---|---|---|---|---|

| Sonora S331 | 3 HP | 190 GPM | 51′ | 3″ | ENG |

| Sonora S333 | 4 HP | 230 GPM | 61′ | 3″ | ENG |

| Sonora S540 | 7 HP | 365 GPM | 92′ | 4″ | ENG |

| Sonora S640 | 9.2 HP | 420 GPM | 100′ | 4″ | ENG |

Slurry Electric Submersible Pumps Specifications

Hydraulic

Sludge & Slurry Hydraulic Submersible Pumps Specifications

La Paz Hydraulic Submersible Pumps

| Model | Volume | Head | Discharge | |

|---|---|---|---|---|

| La Paz 3A-SM | 550 GPM | 300′ | 3″ | ENG |

| La Paz 3D-SM | 600 GPM | 300′ | 3″ | ENG |

| La Paz 3D-TM | 600 GPM | 300′ | 3″ | ENG |

| La Paz 3D-TM-LL | 550 GPM | 250′ | 3″ | ENG |

| La Paz 3D-TM-TA | 600 GPM | 350′ | 3″ | ENG |

| La Paz 4A-SM | 1,000 GPM | 215′ | 4″ | ENG |

| La Paz 4C-SG | 1,150 GPM | 185′ | 4″ | ENG |

| La Paz 4C-TM | 1,150 GPM | 185′ | 4″ | ENG |

| La Paz 4D-SG | 1,200 GPM | 230′ | 4″ | ENG |

| La Paz 4D-SM | 1,000 GPM | 215′ | 4″ | ENG |

| La Paz 4D-TM | 1,200 GPM | 230′ | 4″ | ENG |

| La Paz 4D-TM-TA | 1,325 GPM | 230′ | 4″ | ENG |

Self-Priming Pumps

Appalachian Series Self-Priming Pumps Specifications

Appalachian Self-Priming Surface Pumps

| Model | Power | Volume | Head | Discharge | |

|---|---|---|---|---|---|

| Appalachian 40 | 49HP | 1230 GPM | 164′ | 4″ | ENG |

| Appalachian 60 | 74HP | 2250 GPM | 167′ | 6″ | ENG |

| Appalachian 66K | 74HP | 2640 GPM | 166′ | 6″ | ENG |

| Appalachian 80 | 100HP | 3740 GPM | 164′ | 8″ | ENG |

| Appalachian 88P | 120HP | 3950 GPM | 200′ | 8″ | ENG |

| Appalachian 1212JD | 156HP | 7210 GPM | 153′ | 12″ | ENG |

| Appalachian 1212V | 285HP | 8600 GPM | 225′ | 12″ | ENG |

| High Heads | |||||

| Appalachian H430 | 74HP | 660 GPM | 302′ | 3″ | ENG |

| Appalachian H640 | 275HP | 1950 GPM | 500′ | 4″ | ENG |

| Appalachian H1080 | 235HP | 6400 GPM | 360′ | 8″ | ENG |

Max Series Self-Priming Pumps Specifications

Flooded Suction Pumps

Vertical Pumps Flooded Suction Pumps Specifications

V-Series Flooded Suction Pumps

| Model | Volume | Solids | Intake | Discharge | |

|---|---|---|---|---|---|

| V320 | 730 GPM | 1″ | 3″ | 2″ | ENG |

| V430 | 1100 GPM | 1.1″ | 4″ | 3″ | ENG |

| V540 | 1750 GPM | 3″ | 5″ | 4″ | ENG |

| V640 | 2250 GPM | 1.7″ | 6″ | 4″ | ENG |

| V840 | 2850 GPM | 3″ | 8″ | 4″ | ENG |

| V860 | 4325 GPM | 3″ | 8″ | 6″ | ENG |

| V1060 | 4250 GPM | 3.38″ | 10″ | 6″ | ENG |

| V1080 | 7700 GPM | 3.5″ | 10″ | 8″ | ENG |

| V1210 | 9600 GPM | 3.4″ | 12″ | 10″ | ENG |

| V1412 | 18,000 GPM | 3.5″ | 14″ | 12″ | ENG |

Horizontal Pumps Flooded Suction Pumps Specifications

H-Series Slurry Suction Pumps

| Model | Volume | Solids | Intake | Discharge | |

|---|---|---|---|---|---|

| H151 | 170 GPM | .5″ | 1.5″ | 1″ | ENG |

| H151H | 160 GPM | .6″ | 1.5″ | 1″ | ENG |

| H151R | 140 GPM | .8″ | 1.5″ | 1″ | ENG |

| H215 | 400 GPM | .75″ | 2″ | 1.5″ | ENG |

| H215R | 265 GPM | .63″ | 2″ | 1.5″ | ENG |

| H320 | 490 GPM | 1.9″ | 3″ | 2″ | ENG |

| H320H | 642 GPM | 1.2″ | 3″ | 2″ | ENG |

| H320R | 265 GPM | .8″ | 3″ | 2″ | ENG |

| H430 | 900 GPM | 1.1″ | 4″ | 3″ | ENG |

| H430H | 1600 GPM | 1.5″ | 4″ | 3″ | ENG |

| H430R | 900 GPM | 1.1″ | 4″ | 3″ | ENG |

| H640 | 2200 GPM | 1.7″ | 6″ | 4″ | ENG |

| H640H | 3500 GPM | 2.2″ | 6″ | 4″ | ENG |

| H640R | 1850 GPM | 1.3″ | 6″ | 4″ | ENG |

| H860 | 3800 GPM | 4″ | 8″ | 6″ | ENG |

| H860H | 4750 GPM | 2.75″ | 8″ | 6″ | ENG |

| H860R | 4000 GPM | 2.3″ | 8″ | 6″ | ENG |

| H1080 | 8300 GPM | 3″ | 10″ | 8″ | ENG |

| H1080R | 7100 GPM | 3″ | 10″ | 8″ | ENG |

| H1210 | 9000 GPM | 3.4″ | 12″ | 10″ | ENG |

| H1210R | 8000 GPM | 3.4″ | 12″ | 10″ | ENG |

| H1412 | 16,000 GPM | 3.5″ | 14″ | 12″ | ENG |

| H1412R | 14,670 GPM | 4.1″ | 14″ | 12″ | ENG |

Positive Displacement Pumps

Rotary Pumps

Gear Pumps Positive Displacement Pumps Specifications

Rotary Gear Pumps

Tulare Series Gear Pumps –  Datasheet

Datasheet

| Model | Volume | Speed | Port Size | Pressure | |

|---|---|---|---|---|---|

| Tulare 50 | 1.5 GPM | 1,750 RPM | .5″ | 200 PSI | ENG |

| Tulare 75 | 3 GPM | 1,750 RPM | .5″ | 200 PSI | ENG |

| Tulare 100 | 8 GPM | 1,750 RPM | 1″ | 200 PSI | ENG |

| Tulare 153 | 15 GPM | 1,750 RPM | 1.5″ | 200 PSI | ENG |

| Tulare 156 | 30 GPM | 1,750 RPM | 1.5″ | 200 PSI | ENG |

| Tulare 215 | 67 GPM | 1,450 RPM | 2″ | 200 PSI | ENG |

| Tulare 218 | 80 GPM | 780 RPM | 2″ | 200 PSI | ENG |

| Tulare 220 | 90 GPM | 1,450 RPM | 2″ | 200 PSI | ENG |

| Tulare 223 | 100 GPM | 780 RPM | 2″ | 200 PSI | ENG |

| Tulare 231 | 135 GPM | 640 RPM | 2″ | 200 PSI | ENG |

| Tulare 250 | 135 GPM | 640 RPM | 2.5″ | 200 PSI | ENG |

| Tulare 332 | 140 GPM | 520 RPM | 3″ | 200 PSI | ENG |

| Tulare 345 | 200 GPM | 640 RPM | 3″ | 200 PSI | ENG |

| Tulare 468 | 300 GPM | 520 RPM | 4″ | 200 PSI | ENG |

| Tulare 495 | 420 GPM | 420 RPM | 4″ | 200 PSI | ENG |

| Tulare 611 | 500 GPM | 520 RPM | 6″ | 200 PSI | ENG |

| Tulare 613 | 600 GPM | 350 RPM | 6″ | 200 PSI | ENG |

| Tulare 825 | 1,100 GPM | 280 RPM | 8″ | 200 PSI | ENG |

| Tulare 1036 | 1,600 GPM | 280 RPM | 10″ | 200 PSI | ENG |

Lobe Pumps Positive Displacement Pumps Specifications

Lobe Pumps

| Model | Volume | Speed | Solids | Flange | |

|---|---|---|---|---|---|

| Gala 200 | 72 GPM | 900 RPM | .75″ | 2″ | ENG |

| Gala 300 | 144 GPM | 900 RPM | .75″ | 3″ | ENG |

| Gala 350 | 204 GPM | 600 RPM | 1.5″ | 3″ | ENG |

| Gala 400 | 300 GPM | 600 RPM | 1.5″ | 4″ | ENG |

| Gala 450 | 408 GPM | 600 RPM | 1.5″ | 4″ | ENG |

| Gala 600 | 600 GPM | 600 RPM | 1.5″ | 6″ | ENG |

| Gala 650 | 665 GPM | 500 RPM | 3″ | 4″ | ENG |

| Gala 800 | 1,330 GPM | 500 RPM | 3″ | 8″ | ENG |

| Gala 1000 | 1,995 GPM | 500 RPM | 3″ | 10″ | ENG |

| Gala 1050 | 2,655 GPM | 500 RPM | 3″ | 10″ | ENG |

Open Flow Pumps Positive Displacement Pumps Specifications

Open Flow Pumps

Crest Series Open Flow Pumps

| Model | Size | Capacity | Revolutions | |

|---|---|---|---|---|

| Crest05 | 0.2″ | 6 GPH | 60 RPM | ENG |

| Crest10 | 0.4″ | 48 GPH | 120 RPM | ENG |

| Crest10 3-Lobe | 0.4″ | 19 GPH | 70 RPM | ENG |

| Crest15 | 0.6″ | 158 GPH | 120 RPM | ENG |

| Crest15 3-Lobe | 0.6″ | 111 GPH | 120 RPM | ENG |

| Crest20 | 0.8″ | 270 GPH | 120 RPM | ENG |

| Crest20 3-Lobe | 0.8″ | 177 GPH | 120 RPM | ENG |

| Crest25 | 1″ | 10 GPM | 140 RPM | ENG |

| Crest32 | 1.25″ | 23 GPM | 140 RPM | ENG |

| Crest40 | 1.5″ | 36 GPM | 140 RPM | ENG |

| CrestX40 | 1.5″ | 42 GPM | 120 RPM | ENG |

| Crest50 | 2″ | 70 GPM | 90 RPM | ENG |

| Crest65 | 2.5″ | 91 GPM | 90 RPM | ENG |

| Crest80 | 3″ | 154 GPM | 50 RPM | ENG |

| CrestX80 | 3″ | 121 GPM | 50 RPM | ENG |

| Crest100 | 4″ | 238 GPM | 45 RPM | ENG |

| Crest125 | 5″ | 387 GPM | 40 RPM | ENG |

PeakSeries Open Flow Pumps

Vane Pumps Positive Displacement Puimps Specifications

Vane Pumps

Mirasol Vane Pumps

The DAE Pumps Mirasol vane pumps are the industries most reliable vane pumps for high volume transferring of non-corrosive liquids. Mirasol vane pumps process a variety of liquids ranging in viscosity from thick molasses to thin solvents. The heavy-duty Mirasol pumps provide trouble-free operation with very little maintenance. Our wear-resistant pumps are capable of pumping fluids of up to 200,000 SSU and can reach a maximum capacity of 2,220 GPM at 350 RPM.

Accessories

Hoses Accessory Specifications

Dredge & Slurry Hoses

| Product Name | SLURRY DISCHARGE HOSE |

|---|---|

| Technical Parameters | Tube: NR, BR, SBR Reinforcement: High tensile strength fabrics with helix steel wire Cover: NR, CRNo Negative Pressure |

| Safety Factor | 3:1 |

| Working Temperatures | 20℃ to 80℃ |

| Flange | Standard ANSI 150 PSI Fixed Flange |

| Inner Diameter | Outer Diameter | Thickness of Inner Layer | Working Pressure | Length | Flange ANSI 150 PSI |

|---|---|---|---|---|---|

| 4″ (102 mm) | 5″ (128 mm) | 5/16″ (8 mm) | 150 PSI | 33′ (10 m) | Carbon Steel |

| 6″ (152 mm) | 7″ (182 mm) | 5/16″ (8 mm) | 150 PSI | 33′ (10 m) | Carbon Steel |

| 8″ (203 mm) | 9.3″ (237 mm) | 5/16″ (8 mm) | 150 PSI | 33′ (10 m) | Carbon Steel |

| 10″ (254 mm) | 11.3″ (288 mm) | 5/16″ (8 mm) | 150 PSI | 33′ (10 m) | Carbon Steel |

| 12″ (300 mm) | 13.3″ (338 mm) | 5/16″ (8 mm) | 150 PSI | 33′ (10 m) | Carbon Steel |

Standard ANSI 150 psi Flange Specification

| Normal Diameter | Number of Bolt Holes | Diameter of Bolt Holes | Flange Thickness | Outer Diameter of Flange |

|---|---|---|---|---|

| 4″ (102 mm) | 8 | 5/16″ (18 mm) | 0.89″ (22.5 mm) | 9″ (228 mm) |

| 6″ (152 mm) | 8 | 7/8″ (22 mm) | 0.94″ (24 mm) | 11″ (278 mm) |

| 8″ (203 mm) | 8 | 7/8″ (22 mm) | 1.15″ (29 mm) | 13.5″ (345 mm) |

| 10″ (254 mm) | 12 | 1″ (26mm) | 1.18″ (30mm) | 16″ (405mm) |

| 12″ (300 mm) | 12 | 1″ (26mm) | 1.26″ (32mm) | 19″ (485mm) |

Bend Radius

| Normal Diamete (in)r | Range |

|---|---|

| 4″ (102 mm) | 24.5″-40″ (620 mm – 1020 mm) |

| 6″ (152 mm) | 36″-60″ (920 mm – 1520 mm) |

| 8″ (203 mm) | 48″-80″ (1220 mm – 2030 mm) |

| 10″ (254 mm) | 60″-100″ (1530 mm – 2540 mm) |

| 12″ (300 mm) | 72″-120″ (1820 mm – 3040 mm) |

Floats Accessory Specifications

Pipe & Hose Floats

Flow Meters Accessory Specifications

UFM1000 Doppler Ultrasonic Flow Meters |  UFM1000 Datasheet |

UFM1000 Datasheet |  DFM 6.1 Datasheet

DFM 6.1 Datasheet

DAE Pumps UFM1000 Doppler Ultrasonic Flow Meters provide a highly accurate reading of the slurry flow through the dredge hoses. The ultrasonic flow meter is suitable for monitoring sewage, mud, sludge, and a variety of abrasive solids. A clamp-on, non-intrusive transducers work well on most pipes and hoses constructed from metal or plastic. The DAE Pumps UFM1000 software automatically adjusts filtering parameters and gain settings, ensuring reliable readings over a wide range of liquid and reflector conditions. This flow meter reads any pipe inner diameter from 0.5-in to 15-ft.

UFM1000 is a completely portable package for use in a remote location. This wireless flow meter system consists of the DFM 6.1 with transducer, reader, monitor, and battery pack on a dolly. The DAE Pumps UFM1000 doppler ultrasonic flow meter is housed in a NEMA 4X (IP-66) enclosure and is configured by the user via the front panel keypad. White, backlit matrix displays flow rate, relay states, 16-digit totalizer, operating mode, and calibration menu. Power supply options available to the DAE Pumps UFM1000 doppler ultrasonic flow meter include AC or DC s, and output options include 4-20mA, rate pulse, and dual relay.

The transducer is an SE4 single-head stainless steel ultrasonic with 7.6 m (25 ft) shielded cable and designed to withstand accidental submersion to 10 psi. The transducer is rated to NEMA 6P (IP-68) and can work with temperatures up to 300°F (150°C).

Hydraulic Power Units Accessory Specifications

Hydraulic Power Units | HPUs

Prime Hydraulic Power Units

| Model | Power | Operating Pressure | Hydraulic Flow | |

|---|---|---|---|---|

| Prime 25 | 25 HP / 18 kW | 2250 – 3000 PSI | Up to 17 GPM | ENG |

| Prime 38 | 38 HP / 28 kW | 2250 – 3000 PSI | Up to 17 GPM | ENG |

| Prime 49 | 49 HP / 37 kW | 2500 – 3500 PSI | 4 – 21 GPM | ENG |

| Prime 74 | 74 HP / 55 kW | 2500 – 3300 PSI | 4 – 35 GPM | ENG |

| Prime 127 | 127 HP / 94 kW | 2500 – 3300 PSI | Up to 52 GPM | ENG |

| Prime 154 | 154 HP / 114 kW | 1000 – 4000 PSI | 4 – 95 GPM | ENG |

| Prime 174 | 174 HP / 129 kW | 2500 – 4000 PSI | Up to 80 GPM | ENG |

Generators Accessory Specifications

Industrial Power Generators | Backup Generators

Noble Generators

| Model | Power | Runtime | ENGine | |

|---|---|---|---|---|

| Noble 13 | 20 kW / 25 kVA | 40hrs | Isuzu | ENG |

| Noble 18 | 36 kW / 45 kVA | 30hrs | Isuzu | ENG |

| Noble 28 | 56 kW / 70 kVA | 27hrs | Isuzu | ENG |

| Noble 39 | 76 kW / 95 kVA | 28hrs | John Deere | ENG |

Horton Mobile Generators

| Model | Power | Runtime | ENGine | |

|---|---|---|---|---|

| Horton 25 | 20 kW / 25 kVA | 40hrs | Isuzu | ENG |

| Horton 45 | 36 kW / 45 kVA | 30hrs | Isuzu | ENG |

| Horton 70 | 56 kW / 70 kVA | 27hrs | Isuzu | ENG |

| Horton 95 | 76 kW / 95 kVA | 28hrs | John Deere | ENG |

| Horton 125 | 100 kW / 125 kVA | 23hrs | John Deere | ENG |

| Horton 150 | 120 kW / 150 kVA | 30hrs | John Deere | ENG |

| Horton 200 | 160 kW / 200 kVA | 43hrs | John Deere | ENG |

| Horton 250 | 182 kW / 250 kVA | 44hrs | John Deere | ENG |

| Horton 330 | 264 kW / 330 kVA | 30hrs | John Deere | ENG |

| Horton 700 | 560 kW / 700 kVA | 42hrs | Volvo | ENG |

DUOPack 1500 Power Generator |  Datasheet |

Datasheet |  Engine Datasheet

Engine Datasheet

| Rated Frequency (Hz): | 50 | 60 |

| Rated Power Factor: | 0.8 | 0.8 |

| 3 Phase Voltage (V): | 400/230 | 480/270 |

| Rated Standby Power (kVA/kW): | 1447/1157 | 1588/1270 |

| Rated Prime Power (kVA/kW): | 1365/1092 | 1450/1160 |

| Rated Current (A): | 1970 | 1746 |

| Fuel Autonomy @75% (Hours): | 9 | 8 |

Light Towers Accessory Specifications

Mobile Diesel Light Towers

SITE D5 Mobile LED Light Tower

| Lamps and Wattage: | 4 x 350W |

| Luminosity: | 154,000 Lumens |

| Light Coverage @ 0.5 Footcandle: | 38,000 Ft. |

| Mast Height: | 25 Ft. |

| Engine Model: | Kubota Z482 |

| Speed: | 1800 Single Speed RPM |

| Power: | 4 kWm |

| Load Lever (Lights Only): | 48% |

| Fuel Consumption (Lights Only): | 0.185 GPH |

| Fuel Tank Capacity: | 28 Gallons |

| Runtime Before Refueling: | 150 Hours |

| Enclosure: | PE Double Layer & Spillage Free Frame |

| Mast Finishing: | Hot Dip Galvanized |

| Spillage Free Frame: | Yes |

| Serviceability: | Wide Wing Doors, 100% Access |

| Sound Rating @ 23 ft: | 64 dBA |

| Service Interval: | 400 Hours |

| Outlets: | 120 VAC, 10A, GFCI duplex (NEMA 5-20R) |

| Units on Truck: | 16 |

| Warranty: | 2 Year Unlimited Hours/ Engine 2 Years 2,000 h |

| Dusk/Dawn Photocell + Controller: | Optional |

| Electrical Winch: | Optional |

SITE D4X Mobile Metal Halide Light Tower

| Lamps and Wattage: | 4 x 1,000W |

| Luminosity: | 440,000 Lumens |

| Light Coverage @ 0.5 Footcandle: | 35,000 Ft. |

| Mast Height: | 24.7 Ft. |

| Engine Model: | Kubota 1105 |

| Speed: | 1800 RPM |

| Power: | 10 kWm |

| Load Lever (Lights Only): | 50% |

| Fuel Consumption (Lights Only): | 0.46 GPH |

| Fuel Tank Capacity: | 42 Gallons |

| Runtime Before Refueling: | 90 Hours |

| Fuel System: | Pre Filter, Water Separator, Pump |

| AIR Cleaner: | Dual Stage with Safety Cartridge |

| Enclosure: | PE Double Layer & Spillage Free Frame |

| Mast Finishing: | Hot Dip Galvanized |

| Spillage Free Frame: | Yes |

| Serviceability: | Wide Wing Doors, 100% Access |

| Sound Rating @ 23 ft: | 64 dBA |

| Service Interval: | 200 Hours |

| Outlets: | 120 VAC, 20A, GFCI duplex (NEMA 5-20R) |

| Outlets: | 240 VAC, 30A, TL (NEMA L6-30R) |

| Units on Truck: | 8 |

| Warranty: | 2 Year Unlimited Hours/ Engine 2 Years 2,000 h |

| Dusk/Dawn Photocell + Controller: | Optional |

| Electrical Winch: | Optional |

Variable Frequency Drives Accessory Specifications

Variable Frequency Drive | VFD

| Model | HP | Rated power (KW) | Rated input current (A) | Rated output current (A) | Power loss |

|---|---|---|---|---|---|

| Bear 75 VFD | 75 hp | 55 | 102 | 99 | 1.1 |

| Bear 100 VFD | 100 hp | 75 | 142 | 137 | 1.5 |

| Bear 150 VFD | 150 hp | 110 | 195 | 189 | 2.2 |

| Bear 425 VFD | 425 hp | 315 | 536 | 527 | 6.3 |

| Bear 540 VFD | 540 hp | 400 | 670 | 653 | 8 |

| Bear 750 VFD | 750 hp | 560 | 970 | 560 | 11.2 |

| Bear 845 VFD | 845 hp | 630 | 1065 | 630 | 12.6 |

| Bear 1075 VFD | 1075 hp | 800 | 1360 | 800 | 16 |

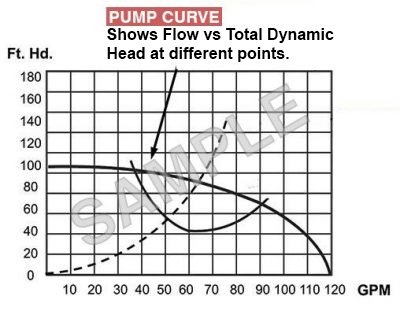

Custom Pump Curve

A pump curve is a graphical representation of a pumps flowrate against a certain level of head. Using a pump curve that is accurate for your application will greatly help in selecting the correct pump, ultimately saving you time and money.

Pump curves are developed from data gathered during testing of the pumps performance at the manufacturer’s facility and provides the end-user with a graph of how the pump will operate over a set range. To build the pump curve, our engineers compile several variables including type of material, fluid viscosity, distance to pump, target GPM, and factors that are job-specific. This ensures the most efficient pump is recommended for your project.

Contact Us Today

Please contact our sales team for product questions or if you need help selecting the best dredge or pump system for your application.

Phone: (760) 821-8112

Email: [email protected]

Live chat: Click to chat

Business Hours: 7:30a-5:30p Monday-Friday